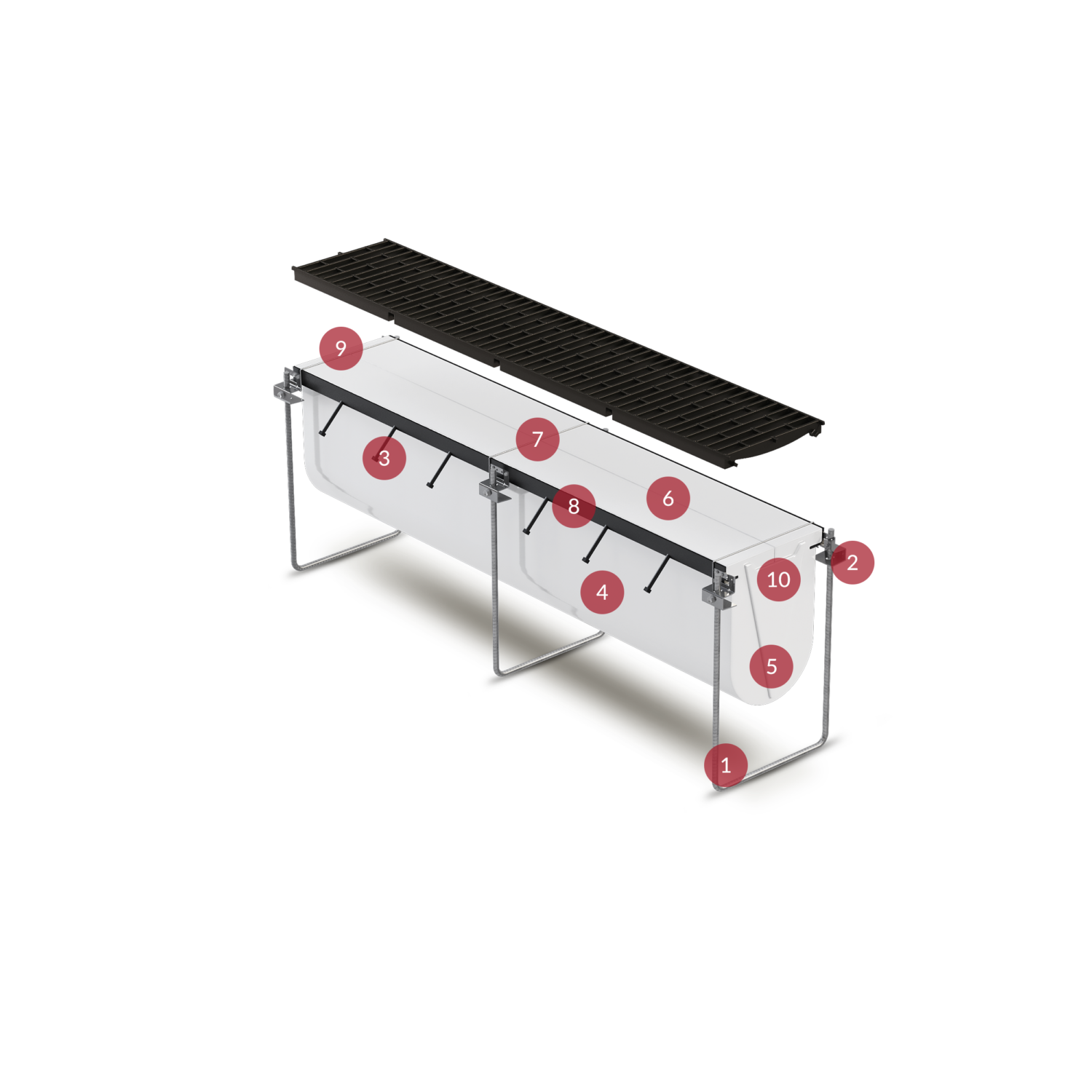

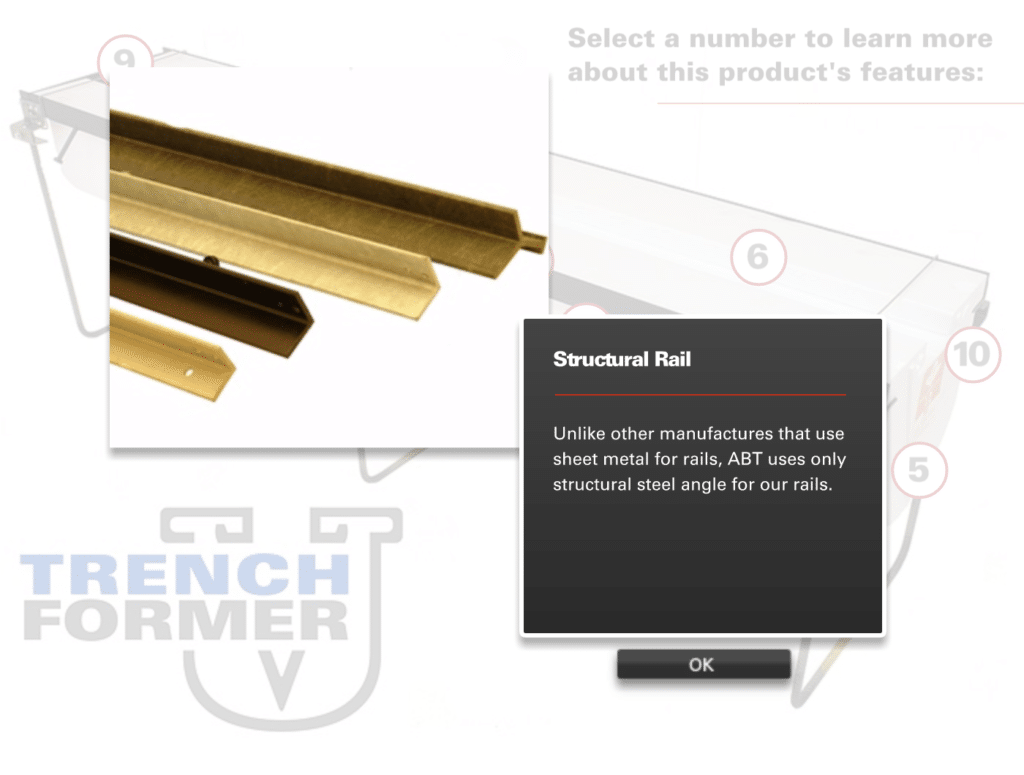

U Leg

No-float U-Legs eliminate subgrade barrier penetration common with most competitors systems and the concrete anchoring slab holds the forming system firmly in place.

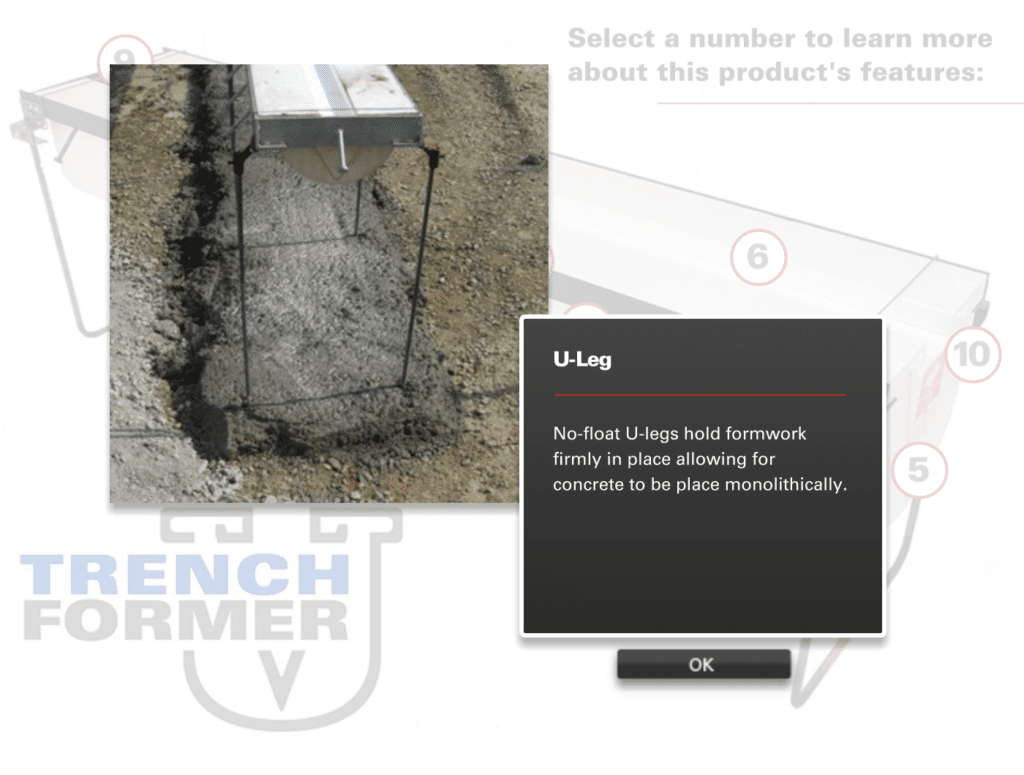

Adjustable Clamp

The adjustable clamp allows the formwork to be micro-adjusted once the anchoring slab is poured over the bottom of the u-legs and prevents uneven joints.

Anchor Studs

Welded concrete studs independently anchor the frame into the surrounding concrete delivering structural load transfer and maximum service life.

EPS Former

Expanded Polystyrene formers can be cut with any desired custom slope and are used to create our standard radius bottom TFX systems, or any custom shape, cast-in-place concrete trench.

Deforming Groove

The center V-shaped section aids installation alignment with the adjoining former sections. After concrete placement, the deforming "V" will break free and enables easy deconstruction of the trench.

Intrinsic Trench Sediment Control and Safety

EPS Formers ensure there are no open trenches during concrete placement and curing. Formers can support light pedestrian traffic and remain in place during construction to serve as an EPA sediment and trash control BMP (best management practice).

Cross Ties

Metal cross ties hold structural steel rails tight to the foam former for consistent horizontal spacing.

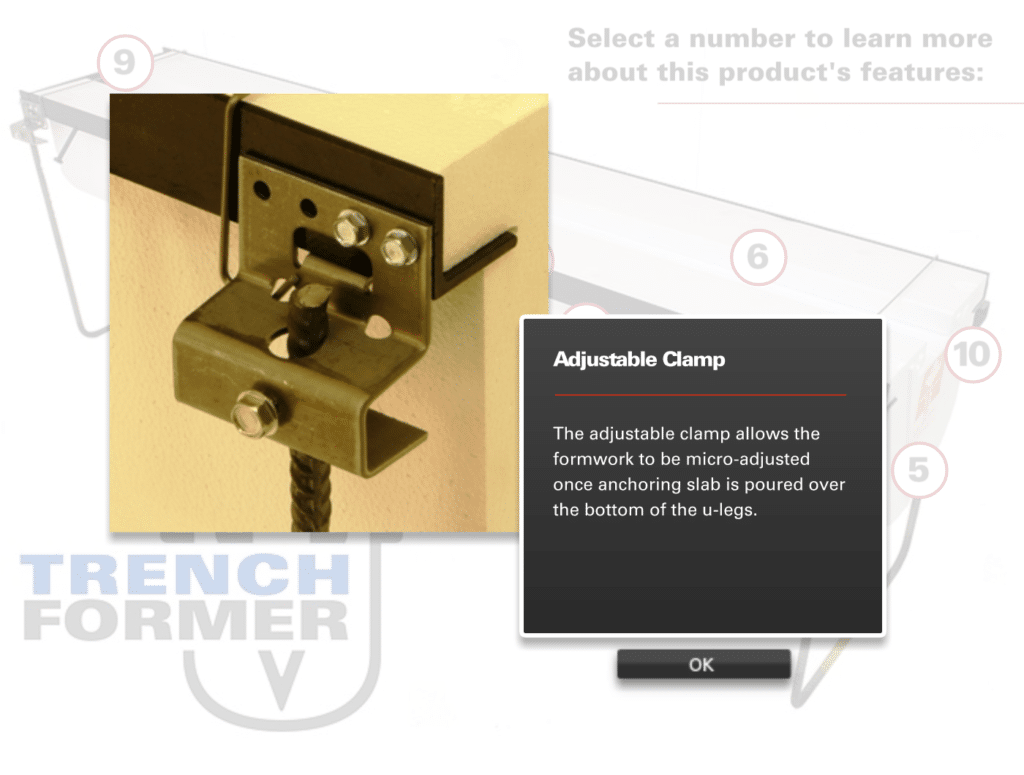

Structural Rail

Most manufacturers use sheet metal overlay rails. Our structural steel angle is independently anchored to maximize load transference into the encasement concrete.

Prefabricated Assemblies

Prefabricated turn and tee assemblies are available and allow quick and easy field installation. Unlike our competitors, load bars come standard in all of our assemblies to reinforce the unsupported rails located at the joint.

Color Coded Labels

Color-coded labels allow easy matching with other system components.