Heavy Duty Cast-In-Place Trench Molds

WHAT HDPE AND FIBERGLASS SYSTEMS HIDE

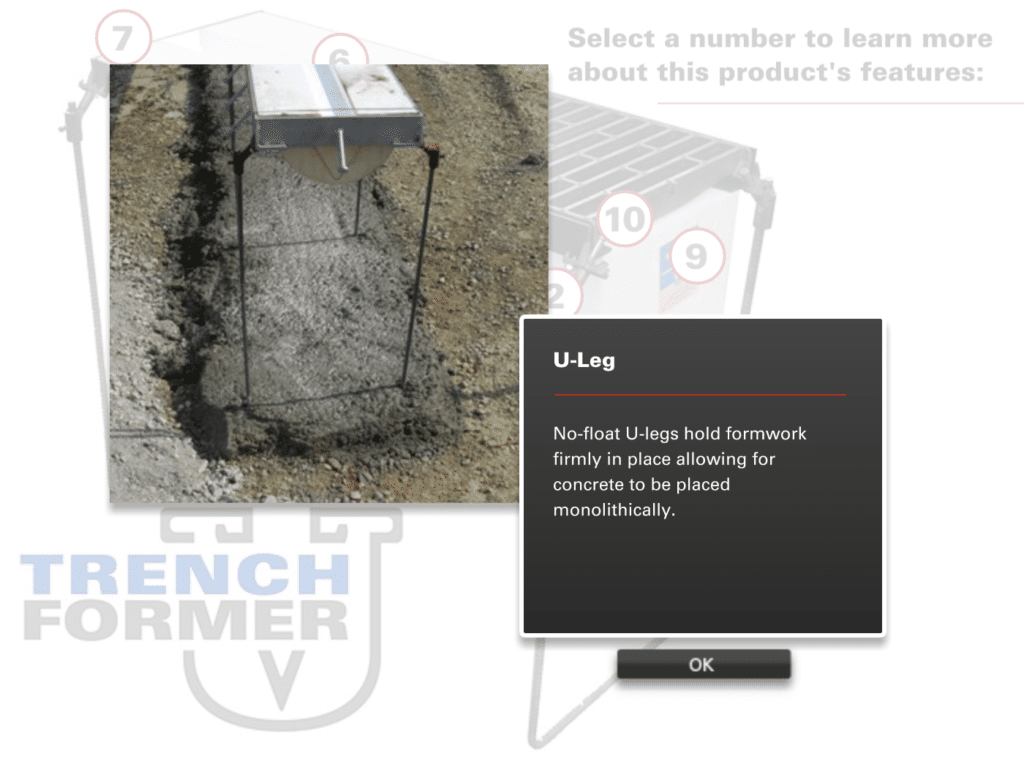

Concrete consolidation under the rail is vital to the longevity of any system in service under heavy loading. Fiberglass and HDPE linear systems can hide construction defects, which can cause costly downtime and ultimately complete system failure.

XHD – EXTREME HEAVY DUTY

AIRPORTS AND PORTS

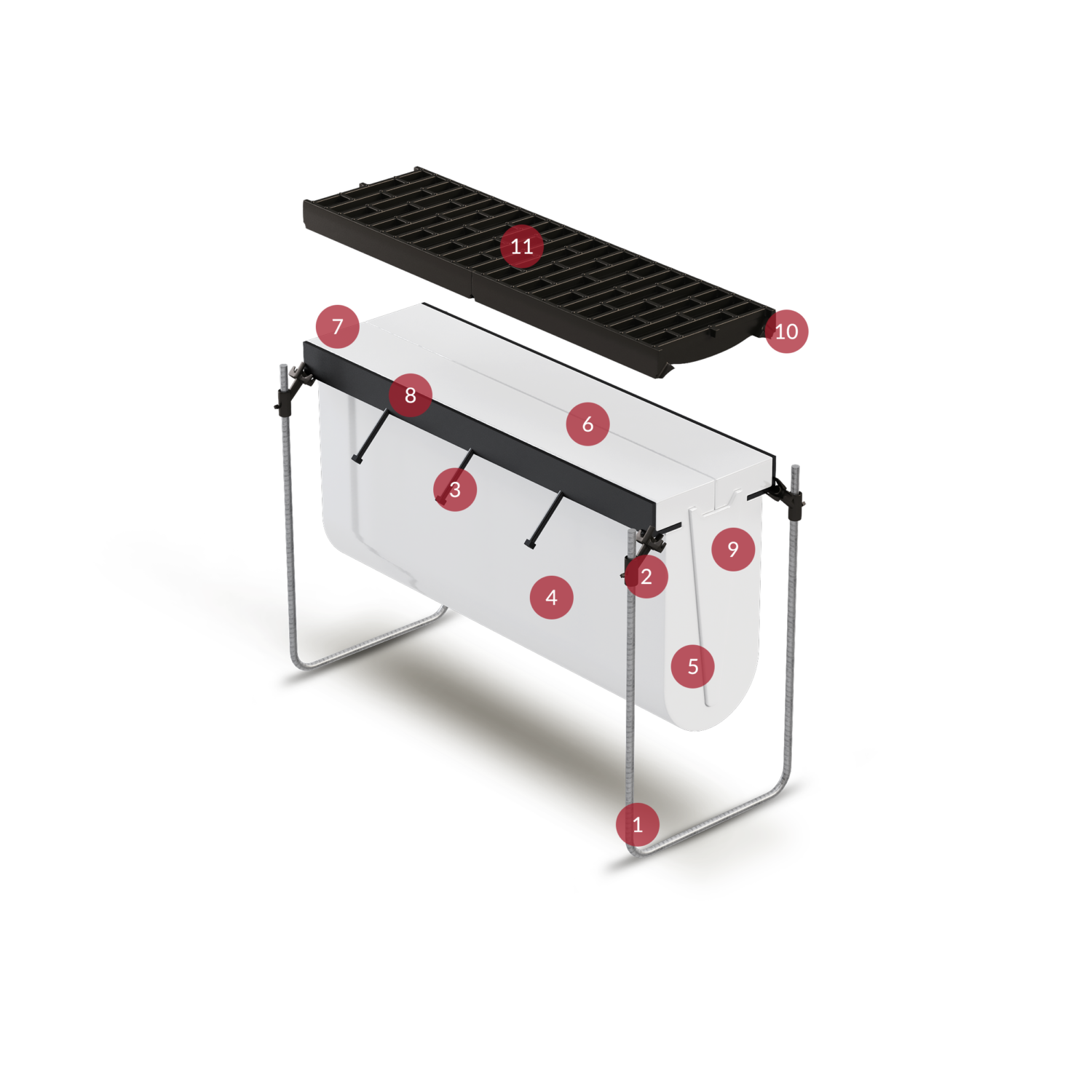

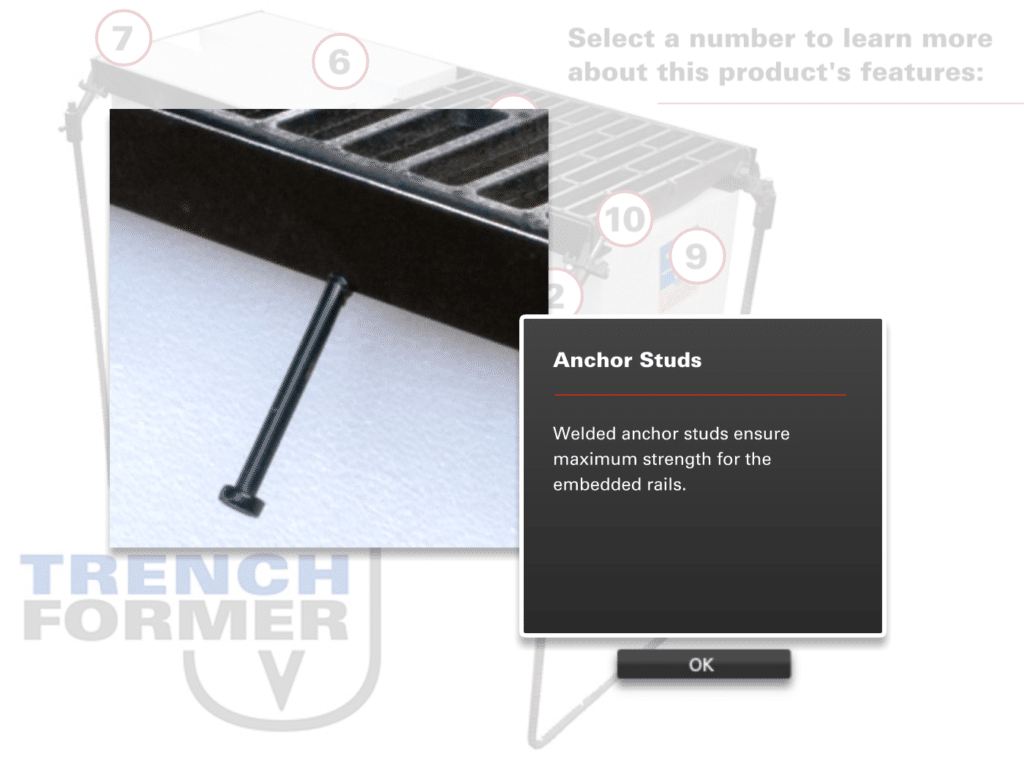

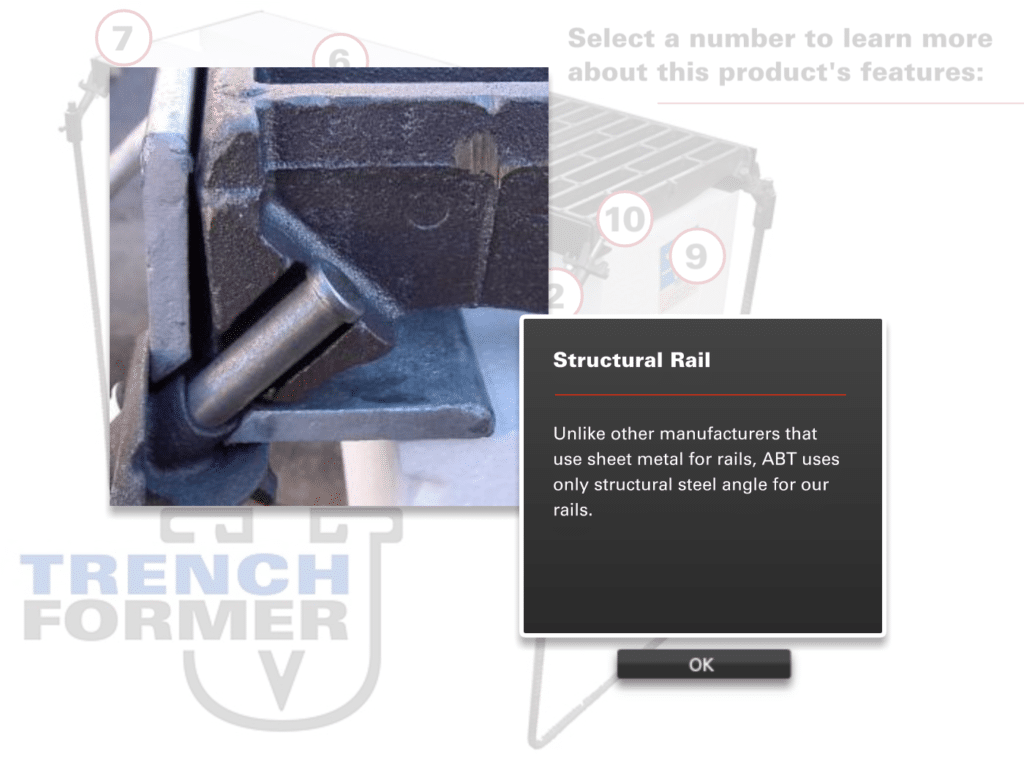

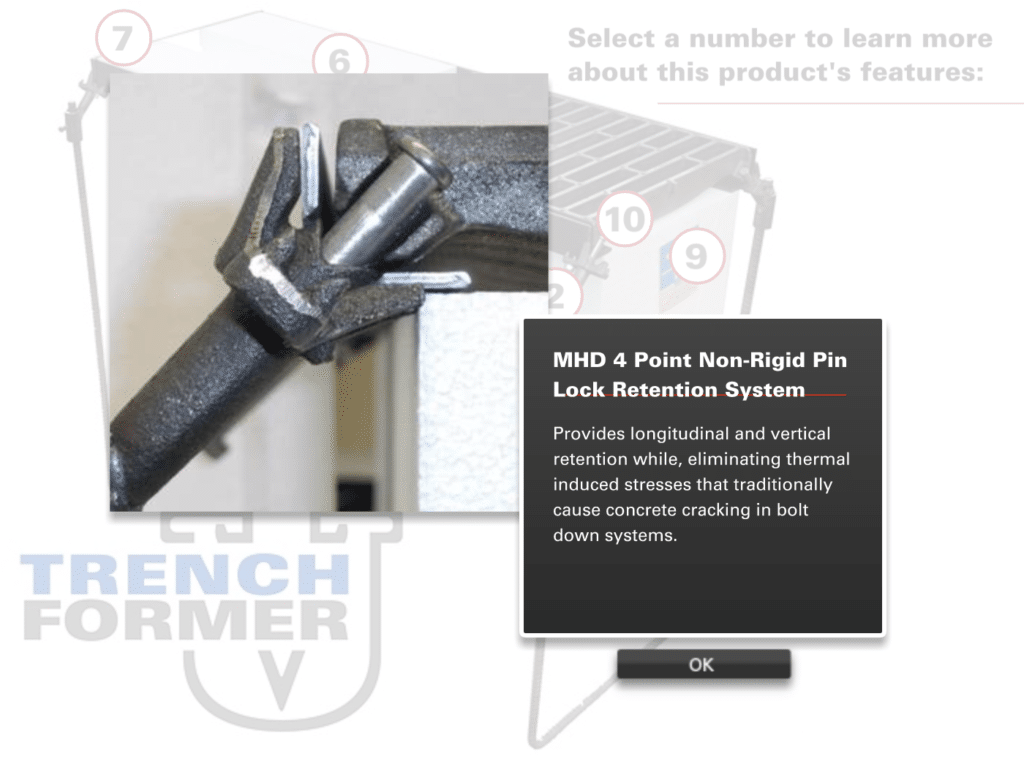

XHD’s steel rails provide concrete bearing width that is the widest in the industry. Also, XHD systems do not create additional failure liability between the rail and concrete by introducing a dissimilar material such as HDPE or fiberglass, that have low compressive strength, creep, or thermal expansion properties. In addition, XHD systems utilize removable bars for grate retention, thus eliminating the tensile stress created by constrained thermal expansion in rigid four bolt systems.

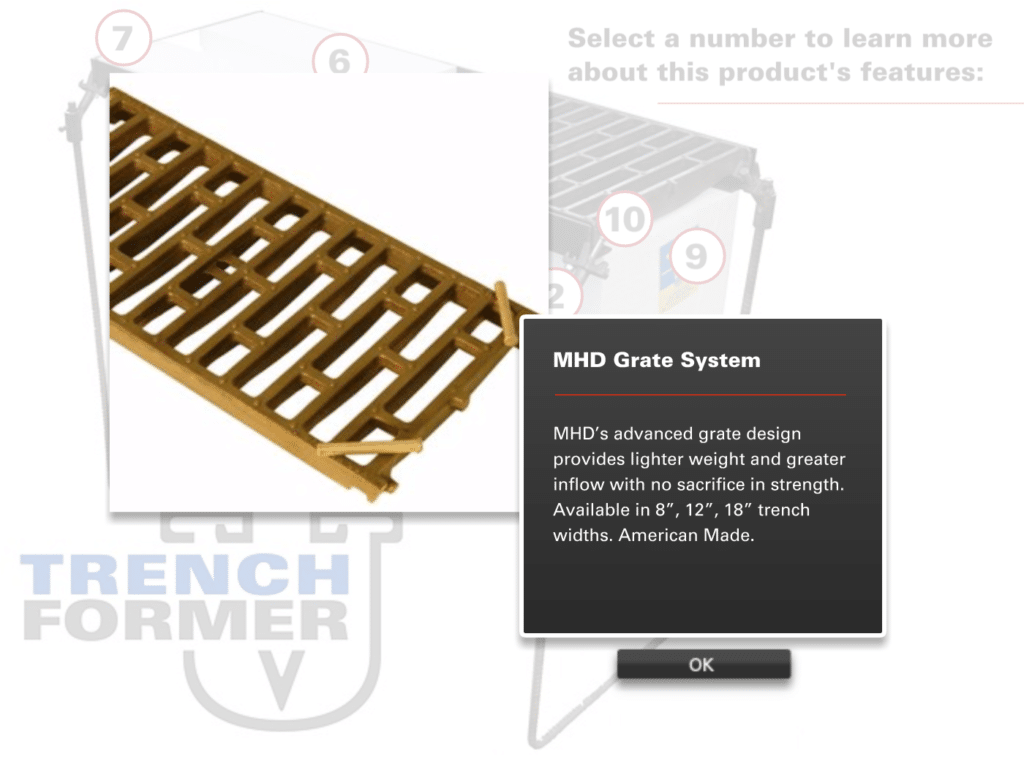

XHD 8″, 12″, 18″ advanced heavy-duty trench drain grate design is not only attractive, but it also provides strength and performance. XHD grates provide the largest inflow area available in cast grates for 8″, 12″, and 18″ trenches while still far exceeding all FAA load ratings.

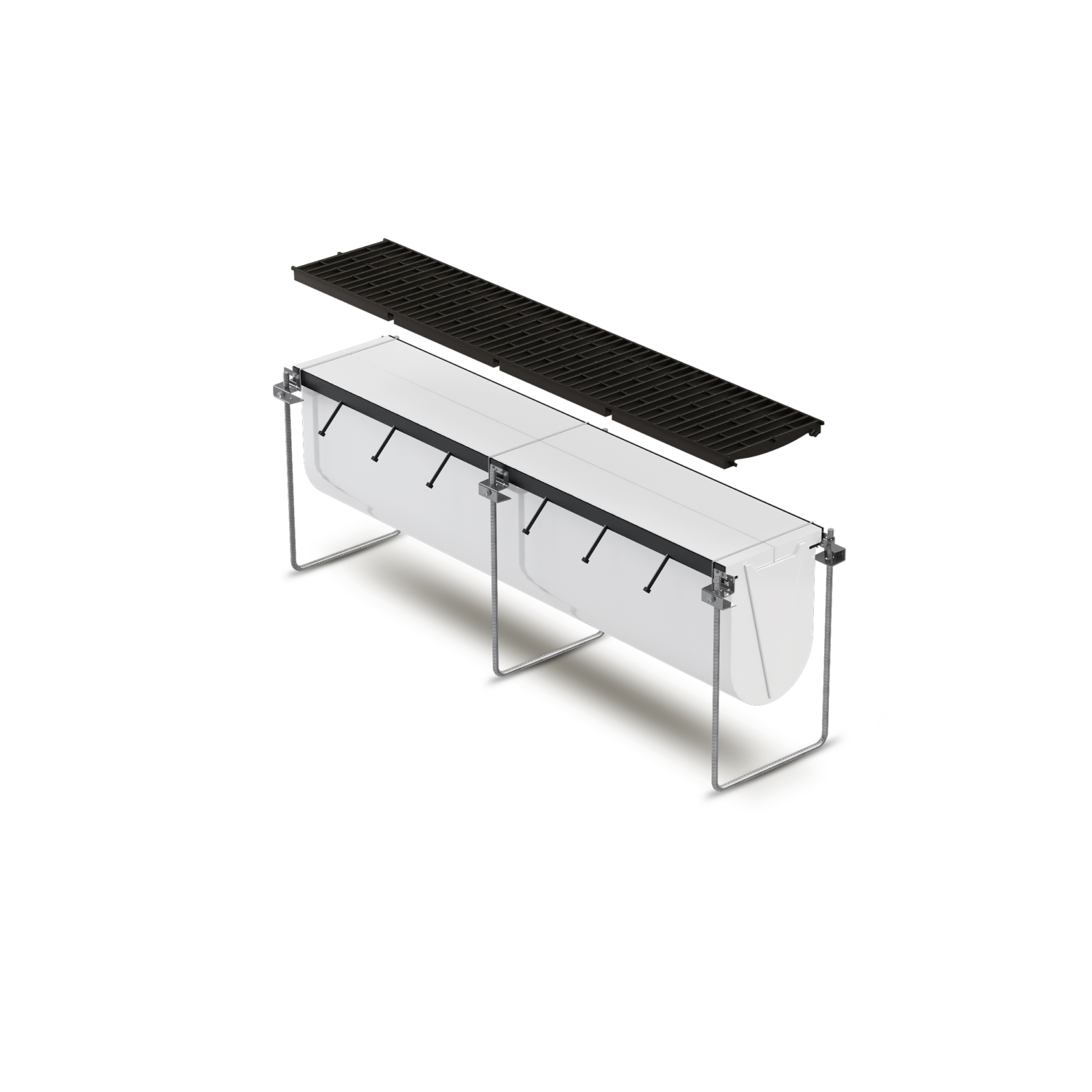

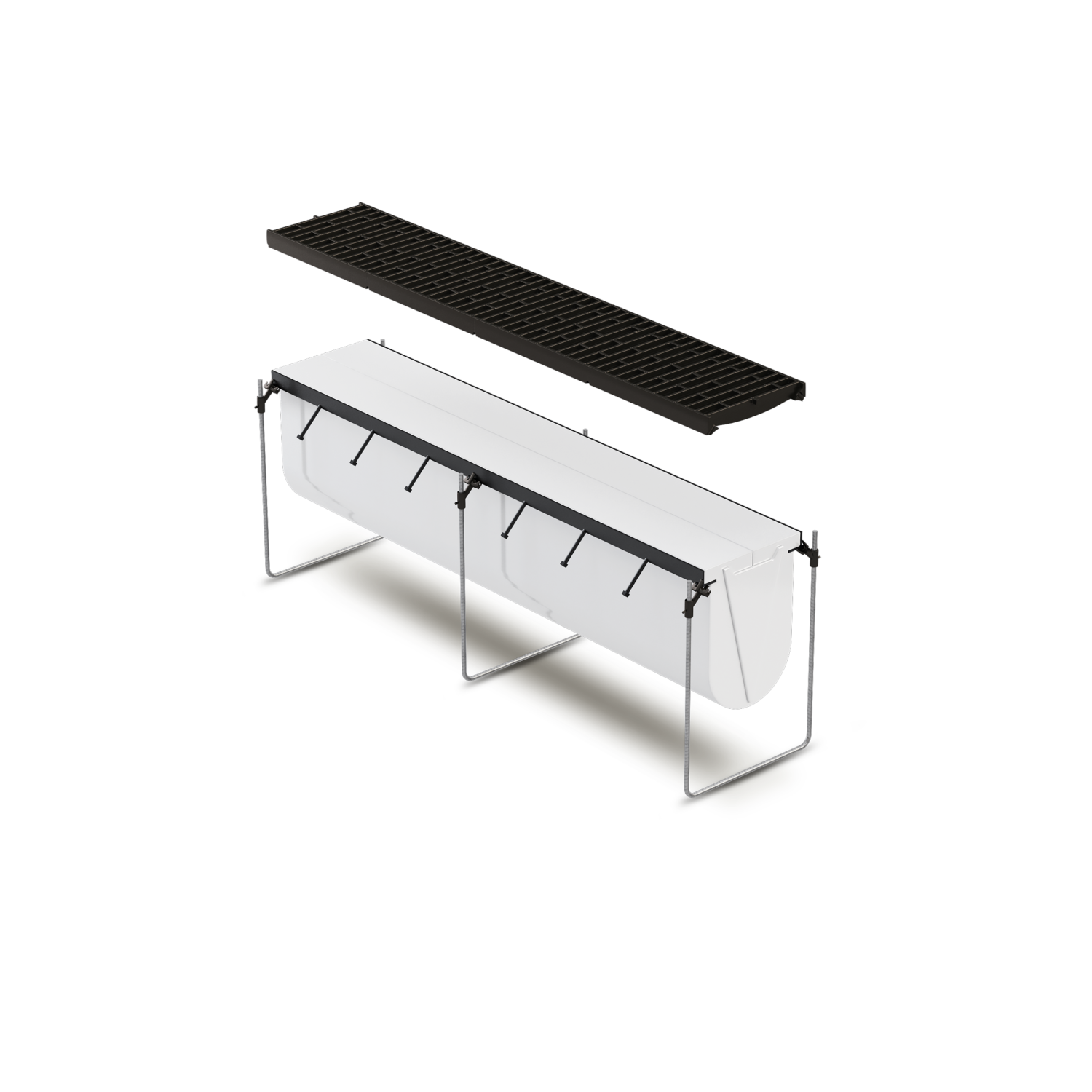

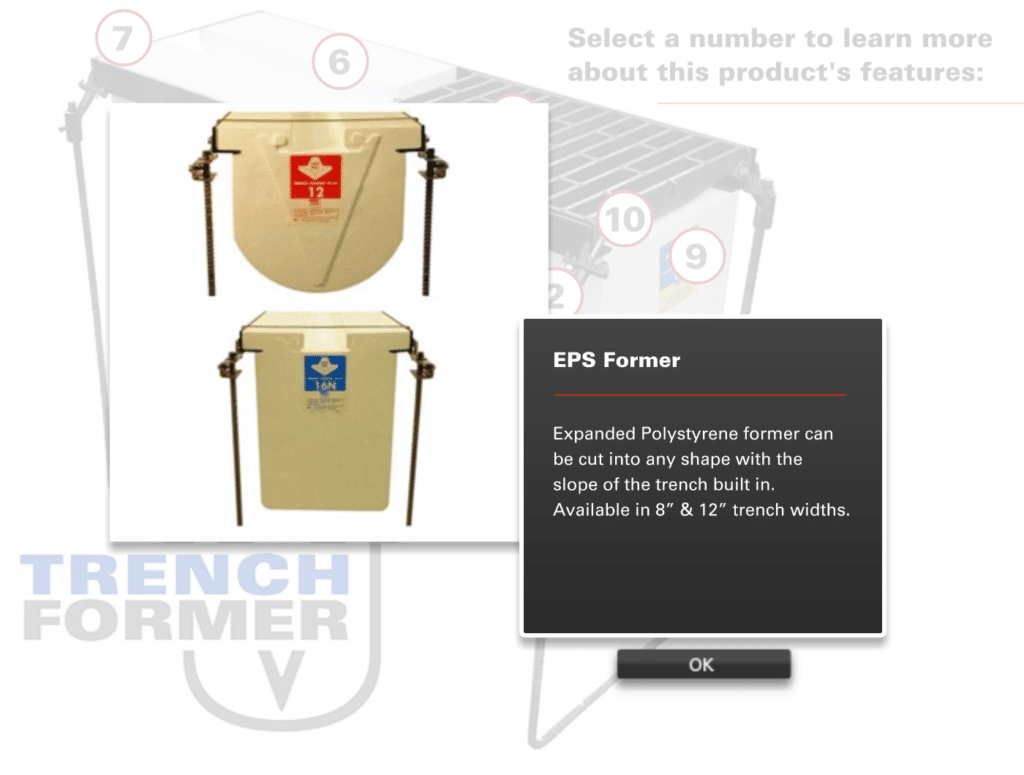

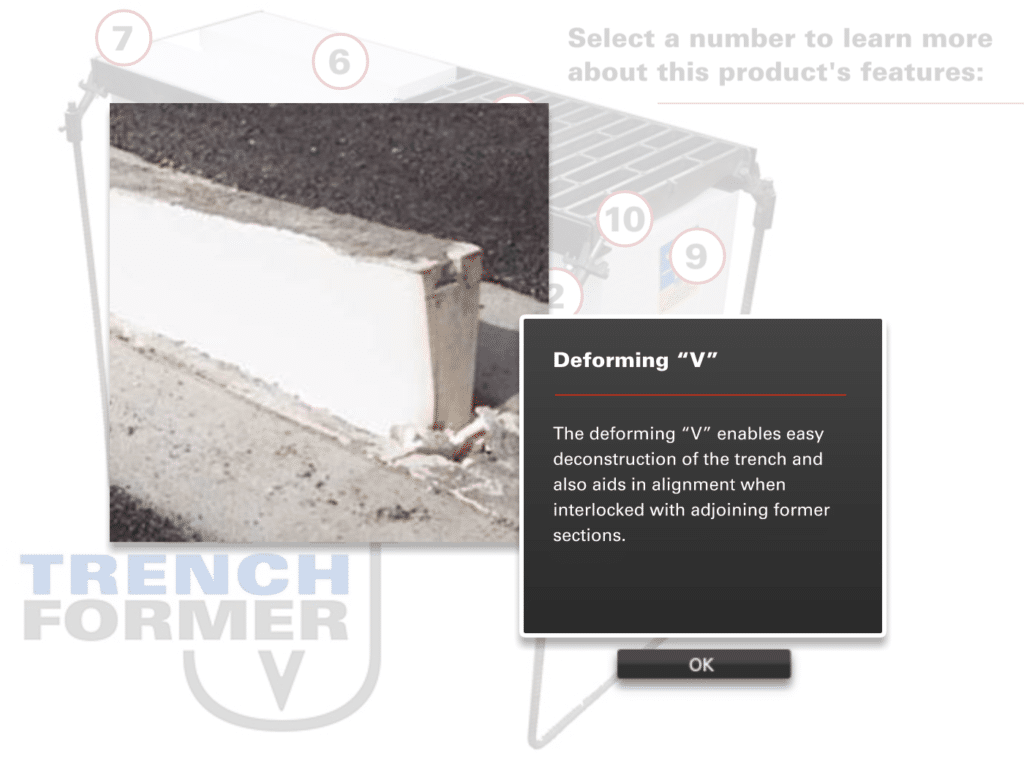

XHD 8″, 12″, 18″ advanced heavy-duty trench drain grate design is not only attractive, but it also provides strength and performance. XHD grates provide the largest inflow area available in cast grates for 8″, 12″, and 18″ trenches while still far exceeding all FAA load ratings. The XHD heavy-duty trench drain molds can be configured for any application’s special flow and depth requirements. A large range of trench drain depths, slopes, and configurations provides an Engineer with greater flexibility for challenging projects. Additionally, the system is pre-engineered and factory fabricated reducing the potential for construction errors in the field.

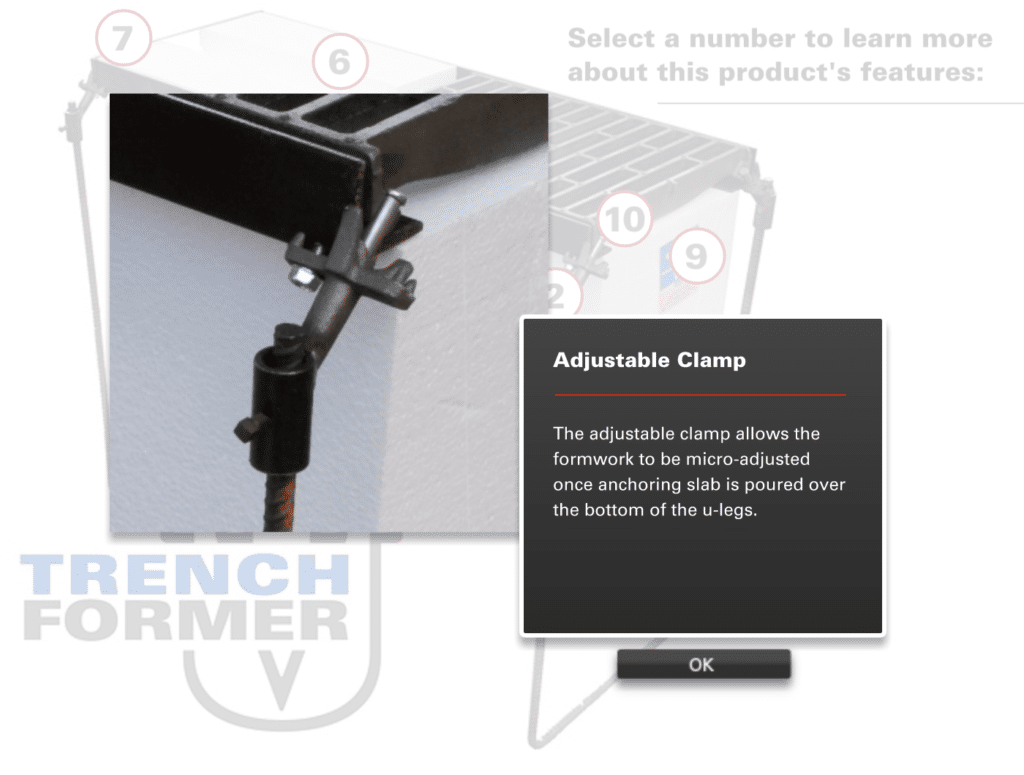

The XHD heavy-duty trench drain molds can be configured for any application’s special flow and depth requirements. A large range of trench drain depths, slopes, and configurations provides an Engineer with greater flexibility for challenging projects. Additionally, the system is pre-engineered and factory fabricated reducing the potential for construction errors in the field.