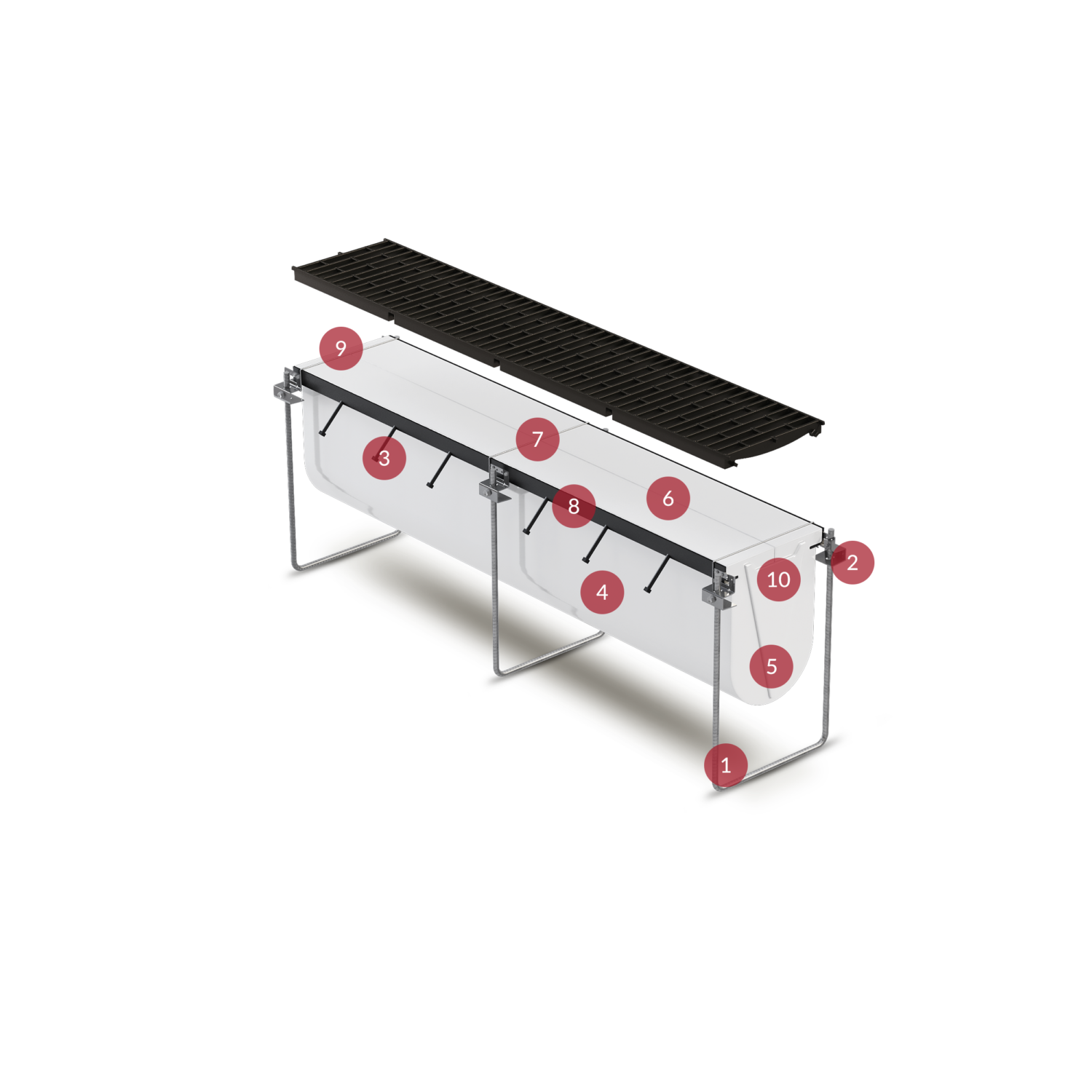

TrenchFormer® Cast-in-Place Forms Product Data

TrenchFormer 6″- 24″

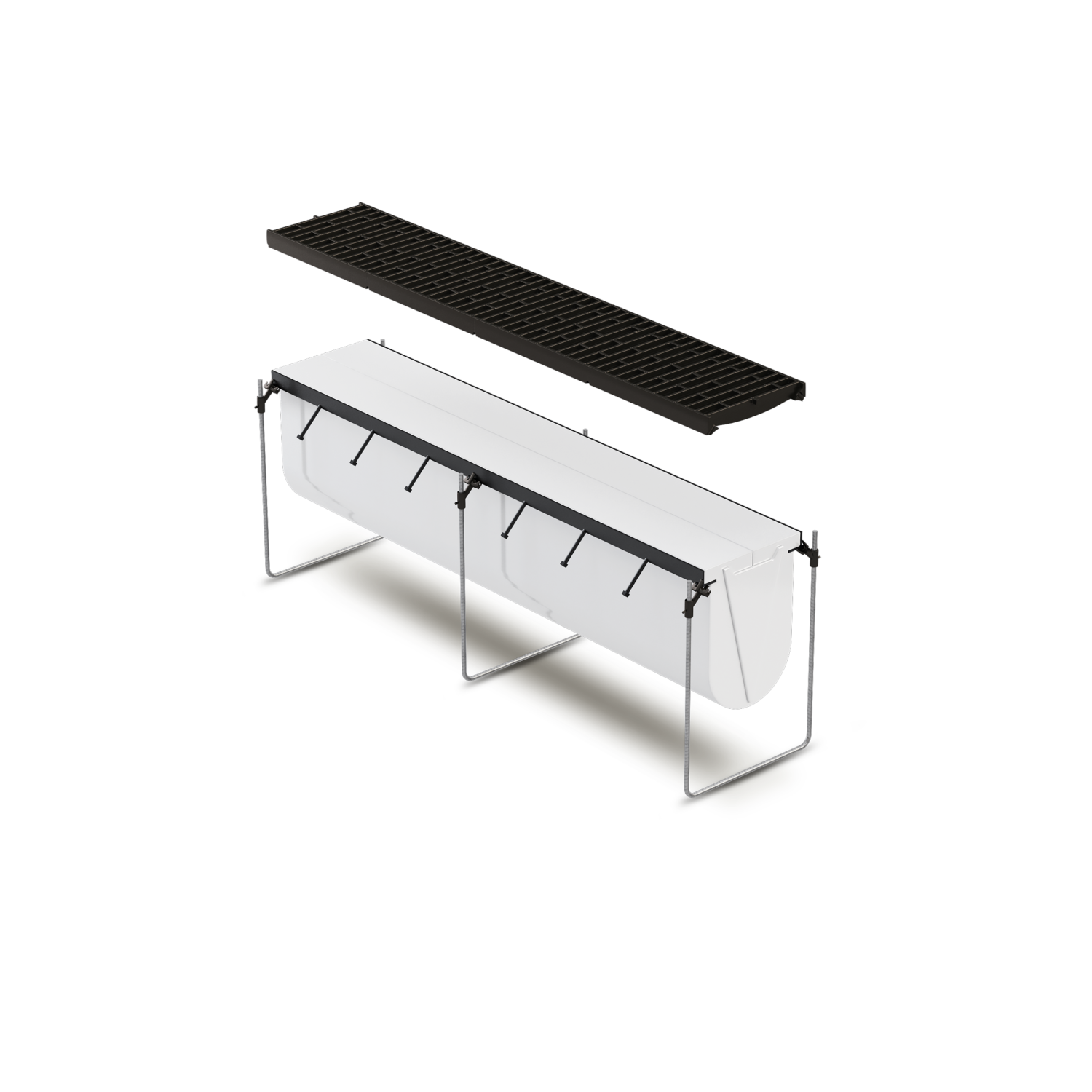

TrenchFormer is a pre-engineered, cast-in-place concrete forming system for forming surface drainage trenches, catch basins, utility chases, and voids in concrete placements. The system includes expanded polystyrene (EPS) form profiles, steel inlay rails, patented no-float legs, grates, and grate retainers. TrenchFormer is available in various width, depths, slopes and trench bottom configurations. TrenchFormer replaces hand-forming, heavy materials, keyways and waterstops normally required with trench drains and utility chases.

Its components are made in the most commonly constructed sizes. TrenchFormer consists of 8 ft. (2.4 M ) pre-sloped form segments. Former sections are available in a variety of slopes.

The segments have integral deforming grooves for easy removal and full length longitudinal grooves for coplanar rail spacing.

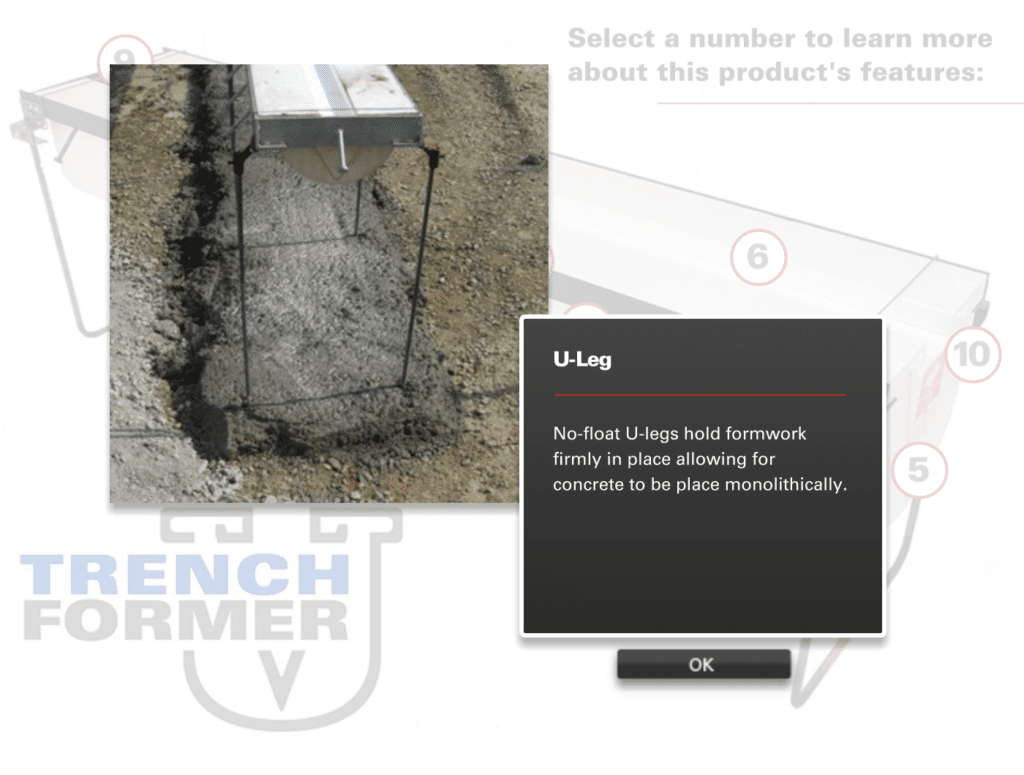

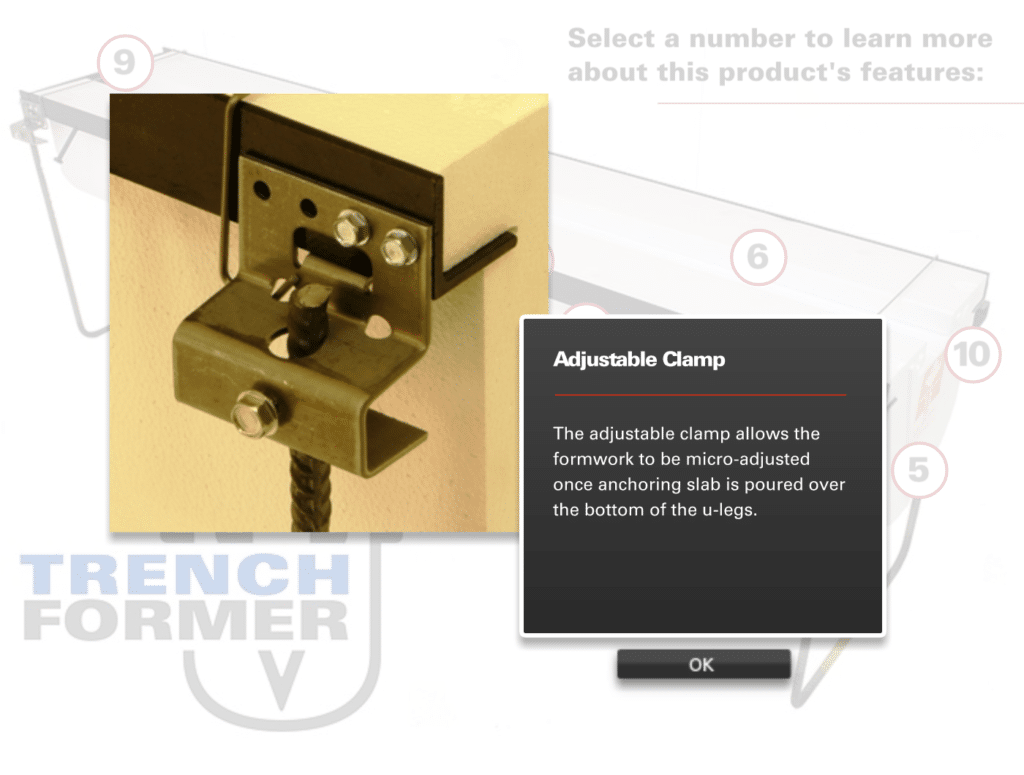

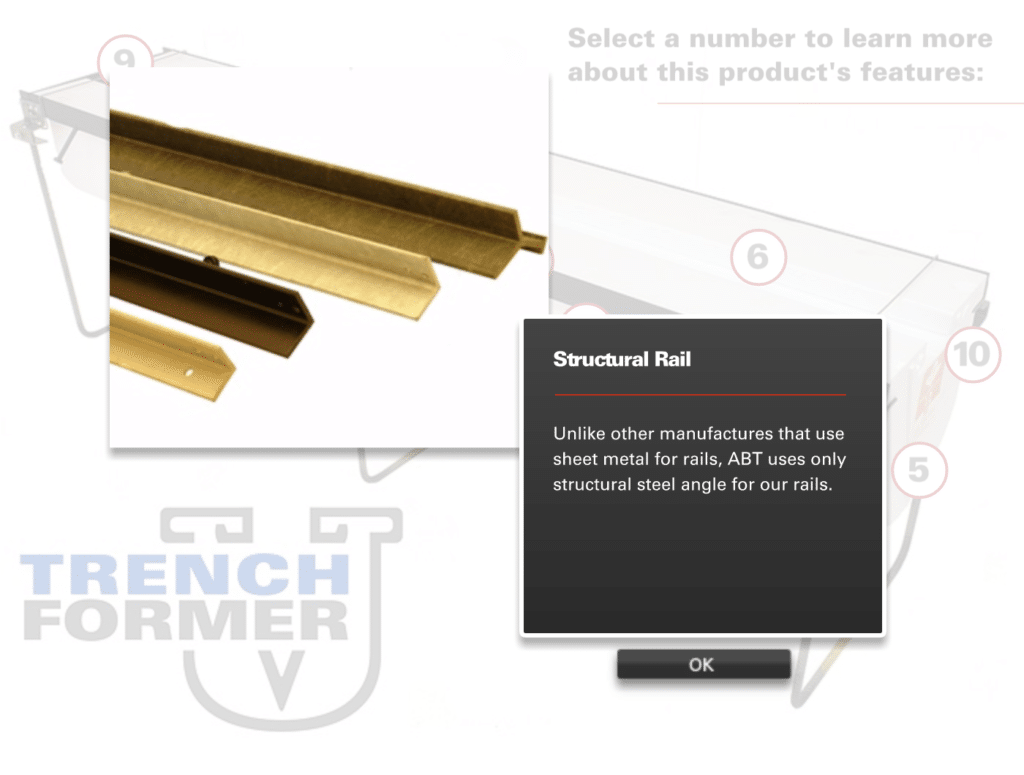

The steel components are angle rails with anchoring studs welded on 11 in. (280 mm) centers to the outside corners. 1/2 in. (12.7 mm) threaded U-shaped no-float legs attach to horizontal tabs on each rail. Each rail end is designed to accept a Rail Alignment Clip which retains adjacent rail segments.

Prefabricated L-rail and T-rail assemblies allow for field installation of 90° turns anywhere in the pre-sloped layout. These assemblies have rail reinforcement built into the areas where the grates are unsupported in other systems. This reinforcement provides load capacity for AASHTO H2O load ratings.

Outlet piping is butted to an annular groove made in the EPS form prior to concreting. For trench junctions or for large outlet sizes, four catch basins are provided. A selection of gratings and solid covers is available for various loadings.

Precision Engineering

Precision is engineered into the TrenchFormer cast-in-place trench drain system, eliminating the need for highly skilled and expensive labor. Accurate to within 1/16″ (1.5 mm), the former shapes have longitudinal grooves for proper rail spacing, and integral deforming grooves for easy removal.

Low Cost Trench Drain Construction

The ABT TrenchFormer cast-in-place trench drain system requires no heavy machinery (except for excavation) and is in place in a fraction of the time of previous cast-in-place trench drain construction methods, reducing installed costs by at least 33%.

Easy Installation

A non-structural anchoring slab placed over the no-float legs holds the form work firmly in place without elaborate anchoring. Concrete can then be placed monolithically, eliminating cold joints, keyways, and waterstop material between the trench drain floor and walls. Forms can be removed in 24 hours or can be left in place indefinitely, preventing unsafe open pits on the job site. There are no piping alignment problems because piping is butted to the form work and cast-in-place.

Environmentally Sound

The TrenchFormer EPS forming medium is manufactured without chlorofluorocarbons for easy and safe disposal. The forming medium is recyclable, makes a high quality fuel for commercial incinerators.

Low Maintenance

The ABT TrenchFormer cast-in-place trench drain system components are designed for long service life. The steel rails are either powder epoxy coated or galvanized. Drain grates and covers are of uncoated ductile iron, grey iron, or galvanized steel. The trench drain built-in slope and radius bottom features help to eliminate debris buildup make the trench drain system virtually maintenance free.

Versatility

The strength of the TrenchFormer System is its ability to be economically modified to provide the correct solution. Trench width, depth, cross section shape, rail size, rail material, invert slope, system strength, etc. can be changed to meet the application’s requirements.

The TrenchFormer cast-in-place concrete forming system for forming trench drains, catch basins, utility chases, and voids in concrete placement is manufactured by ABT Inc., the industry leader in modular drainage systems for commercial and industrial use.